Projects

Atomic

‘In professional sports, material that can be individually adapted to the body can be a real asset!’

Atomic

Top performance with customised inner ski boots and insoles

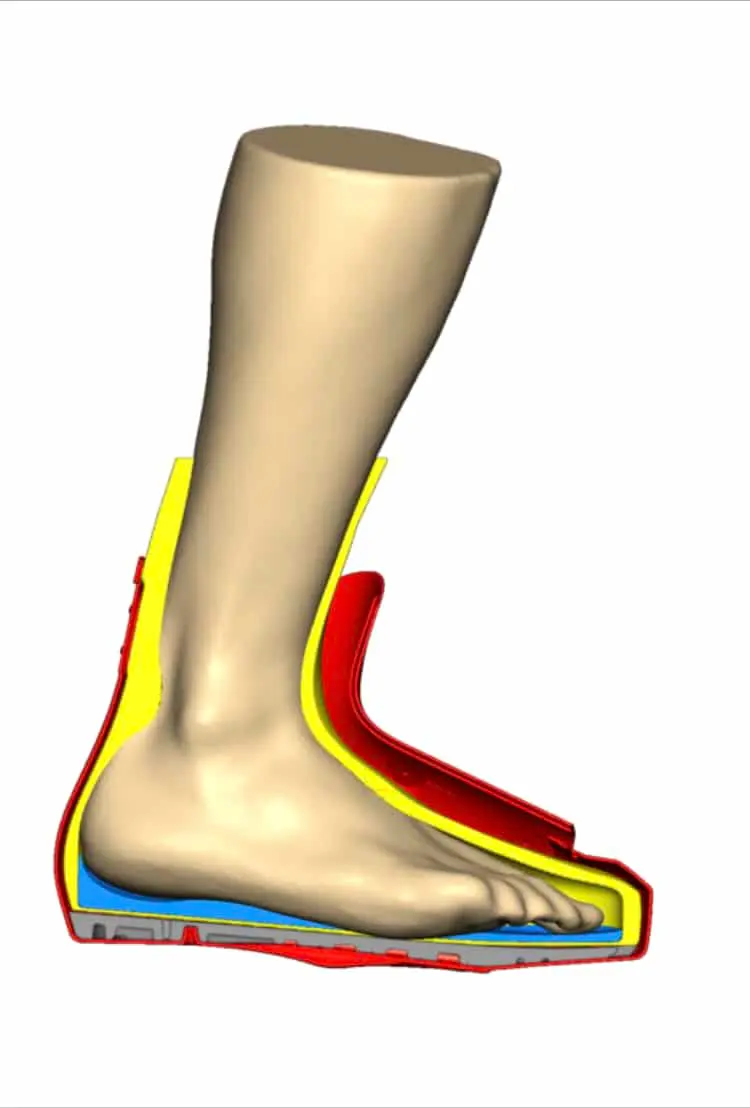

Top-level sport is all about peak performance, and materials science and digitalisation play a key role in this. Atomic, which WAKO got to know through its involvement with the Pilz Health Centre, conducted a preliminary project to investigate whether customised inner ski boots and insoles with 3D cushioning could improve the skiing performance of professional athletes.

What helps with misalignments can also be beneficial in everyday life – and especially in high-performance sports. We developed a 3D-printed inner ski boot for Atomic that was individually tailored to the foot and leg. In practice, however, it became apparent that the inner boot fit too well – leaving too little room for the foot to move. The cushioning of the insoles, however, could be developed into a further project.

ce:koon

‘Our own product demonstrates what we are capable of – thinking innovatively, implementing smooth workflows and using digitalisation to create better and simpler products.’

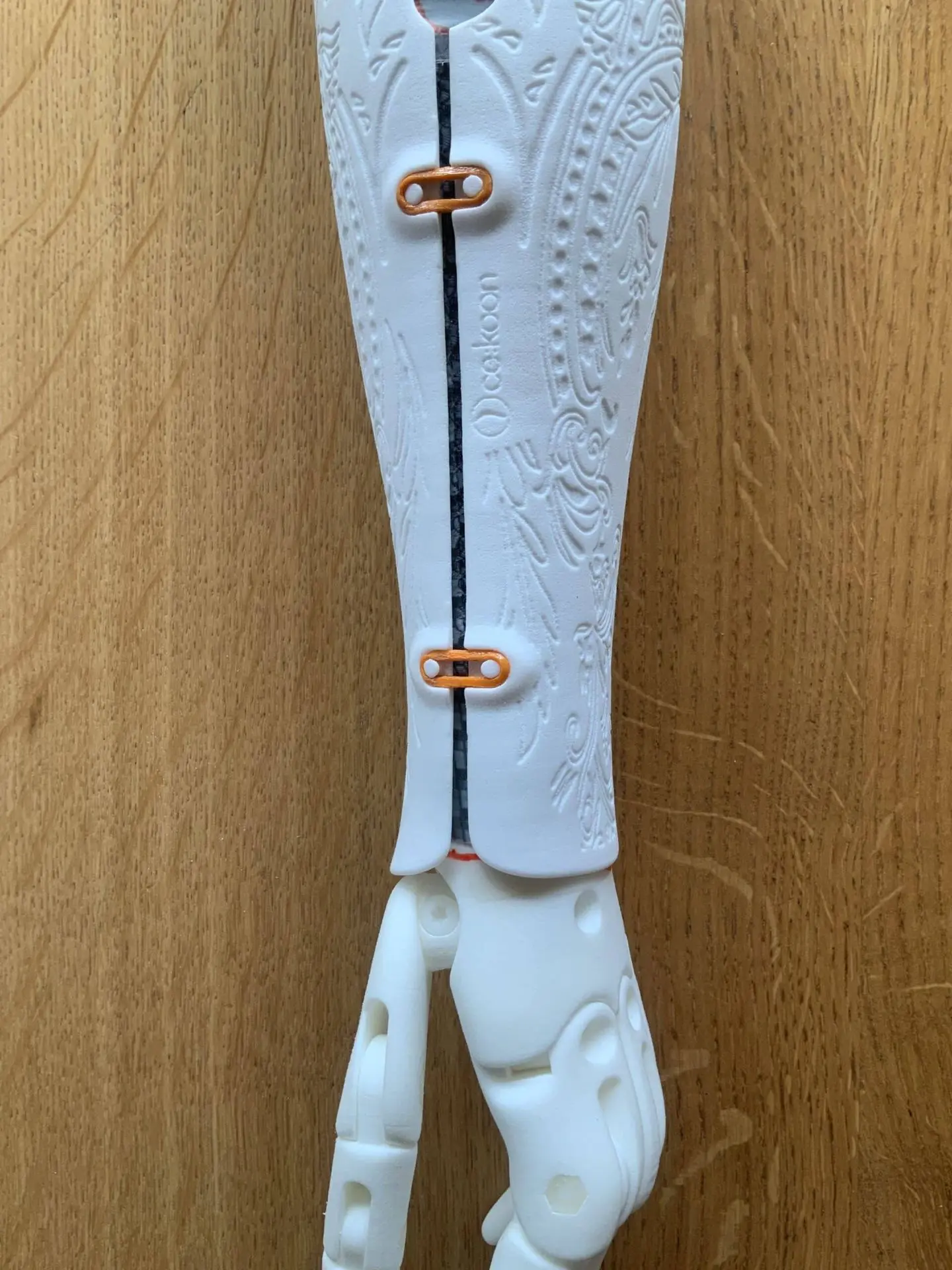

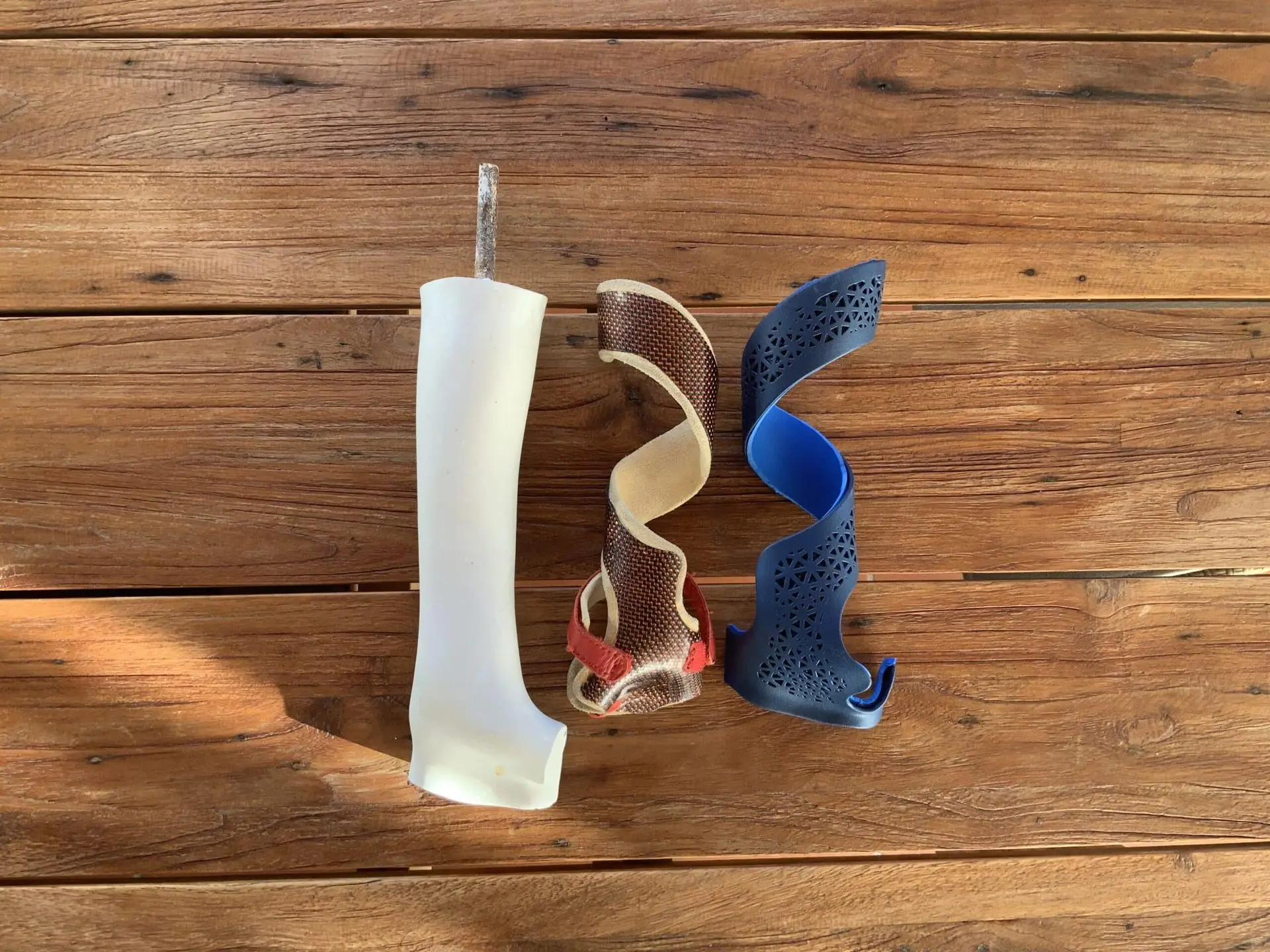

Prosthetic covers: fashionable accessories and medical aids

There was more or less a gap in the European market for prosthetic covers – especially if you valued a smart and individual design that not only protects the prosthesis but also emphasises your own personality.

Markus Wakolbinger, founder of WAKO, quickly realised that he could help with his 3D expertise. The covers he developed not only look different from anything that has come before, they can also be used for all types of upper and lower leg prostheses. The covers are soft, flexible, sporty and lightweight, and are characterised by their individual fit. What's more, they are easy to attach. Several health insurance companies in Germany already cover the costs – because these stylish covers, which are more like jewellery than medical aids, also support the healing process and the psyche.

Wakolbinger Car Upholstery

‘Restoring classic cars is often difficult because spare parts are no longer available. We solve this challenge with 3D printing!’

Manfred Wakolbinger, owner of Wakolbinger car upholstery

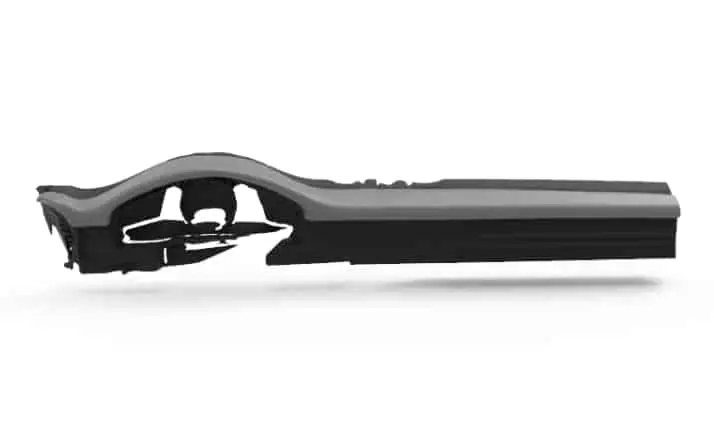

Spare parts no longer available for the restoration of classic cars

Manfred Wakolbinger has been working successfully as an automotive upholsterer in St. Veith im Mühlkreis for 10 years. It is part of his everyday life that spare parts are no longer available for the decades-old cars in his workshop.

With the help of our technology, we scan, model and produce the right spare parts using 3D printing, which not only meet the requirements of vehicle construction in terms of shape, but also in terms of rigidity. This means there are no limits to the restoration of classic cars, convertibles, motorcycles, etc. Wakolbinger is more than satisfied: he also sees 3D potential for his second business, the restoration of old furniture. With the help of our Aidddo platform, he plans to offer a digital workflow for the restoration of upholstered furniture.

OTH Döbling – Specialist in prostheses

‘Our goal: to put our founders' incredible expertise on a digital footing!’

OTH Döbling

Digitising knowledge and making it usable for the future

Hans Opel and Rene Hockenhofer are world-leading experts in leg and arm prostheses. The idea of turning their high-quality prostheses into everyday jewellery with equally high-quality Ce:koon covers led to a fruitful collaboration with WAKO. The company currently still produces its prosthetic sockets in the traditional way – by hand.

Our common goal in the current prototyping process is to convert production to a digital 3D workflow in the medium term, so that the knowledge of the two founders can be retained for the company even after their retirement and production can continue at the same high quality but in a more contemporary manner.

Bandagist Schaper

‘Customised products are more efficient – and branding helps us strengthen our brand at the same time.’

Schaper Healthcare GmbH

Improve products while strengthening your own brand

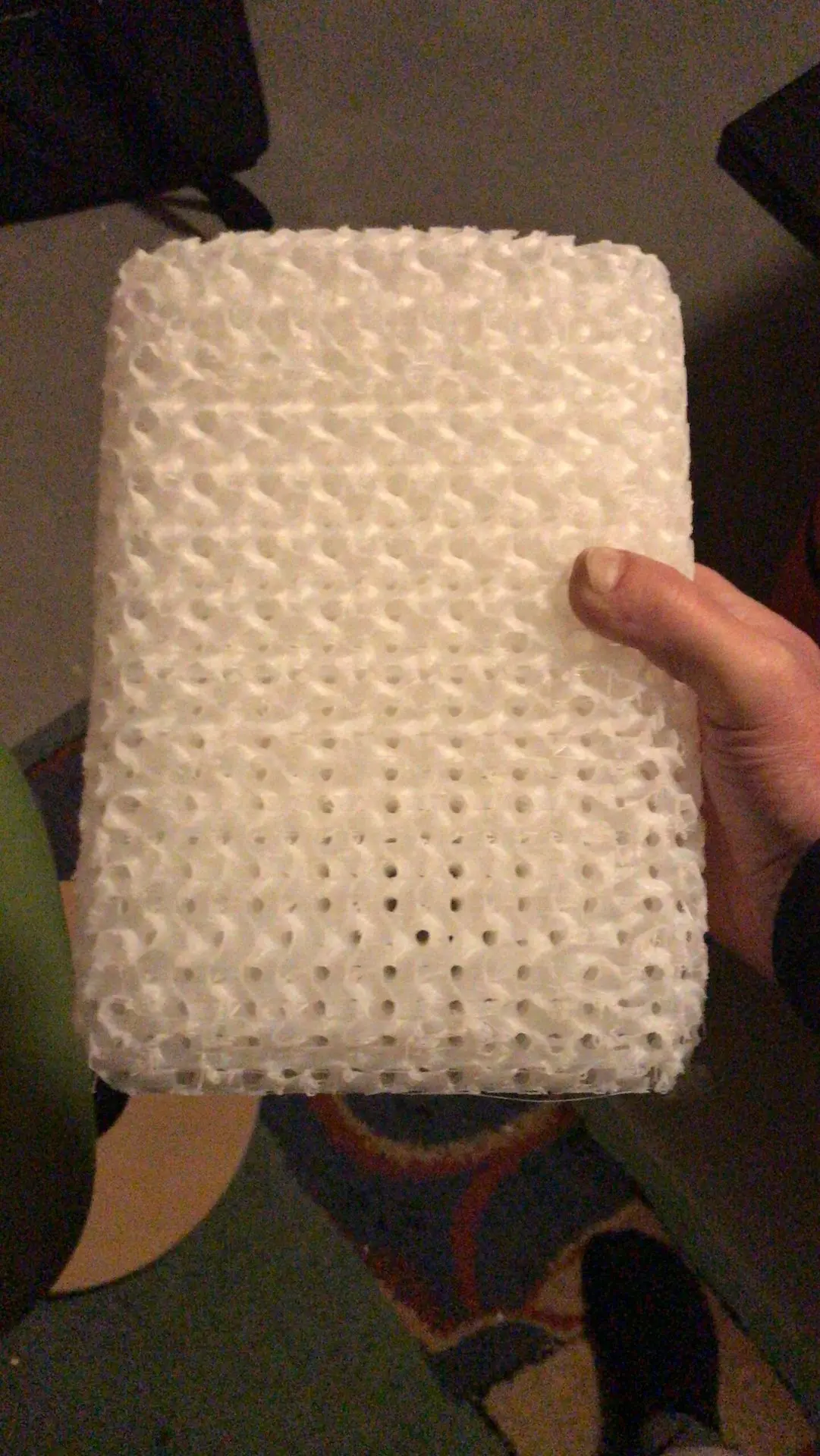

The well-known Wels-based bandage supplier sells numerous orthopaedic products, including ankle braces. This product was previously available in four sizes, with a left and right version for each size. Such a large number of different variants is very complex for patients and also less than ideal for customers' stock management.

WAKO developed a custom ankle orthosis for Schaper that can be used on both feet. In addition, improvements to the fit (digital adjustment using 3D foot scans) mean that only three different sizes are now required. This reduction from eight to three different variants is an enormous advantage, especially in terms of storage for Schaper's customers (hospitals, doctors, etc.). Inspired by our joint success, we are already working on further customised Schaper products such as stiffening orthoses and Velcro fasteners, which also highlight the brand thanks to branding that is easy to implement using 3D printing.

Pilz Health Centre

‘We had had our own 3D printer in operation for a long time. But it only really got going with the support of WAKO!’

Stefan Pilz, Managing Director, Orthopedics Pilz GmbH

Driving innovation forward together

The renowned company, headquartered in Perg, was open to the potential of 3D printing in orthopaedics from the outset – and already had its own printer in-house. The advantages were obvious to Pilz: 3D-printed orthoses can be light and airy, joints do not need to be cast, and individual production is always perfectly accurate thanks to body scanning. However, the company lacked the time and expertise of its employees to model product ideas and set up efficient workflows.

We therefore supported the Pilz Health Centre with 3D printing services such as 3D modelling and setting up an effective workflow, as well as advising on funding opportunities for their digitalisation projects. The collaboration has resulted in further 3D product developments and several joint projects between Pilz and WAKO, ranging from fully digital and fully automated production of customised shoe insoles to ski boot orthoses for amateur and professional athletes.